The world's best companies trust Visionfacts

Safer facilities, greater efficiency

Manage site safety from anywhere.

Effortlessly manage facilities with AI. It makes it seamless to manage operations and monitor security effectively analyzing video footage and responding to glitches with their occurrence.

Accurate & rapid detection

Analyzing video in real-time and adjusting its performance based on the data, it constantly improves its performance and generates actionable insights.

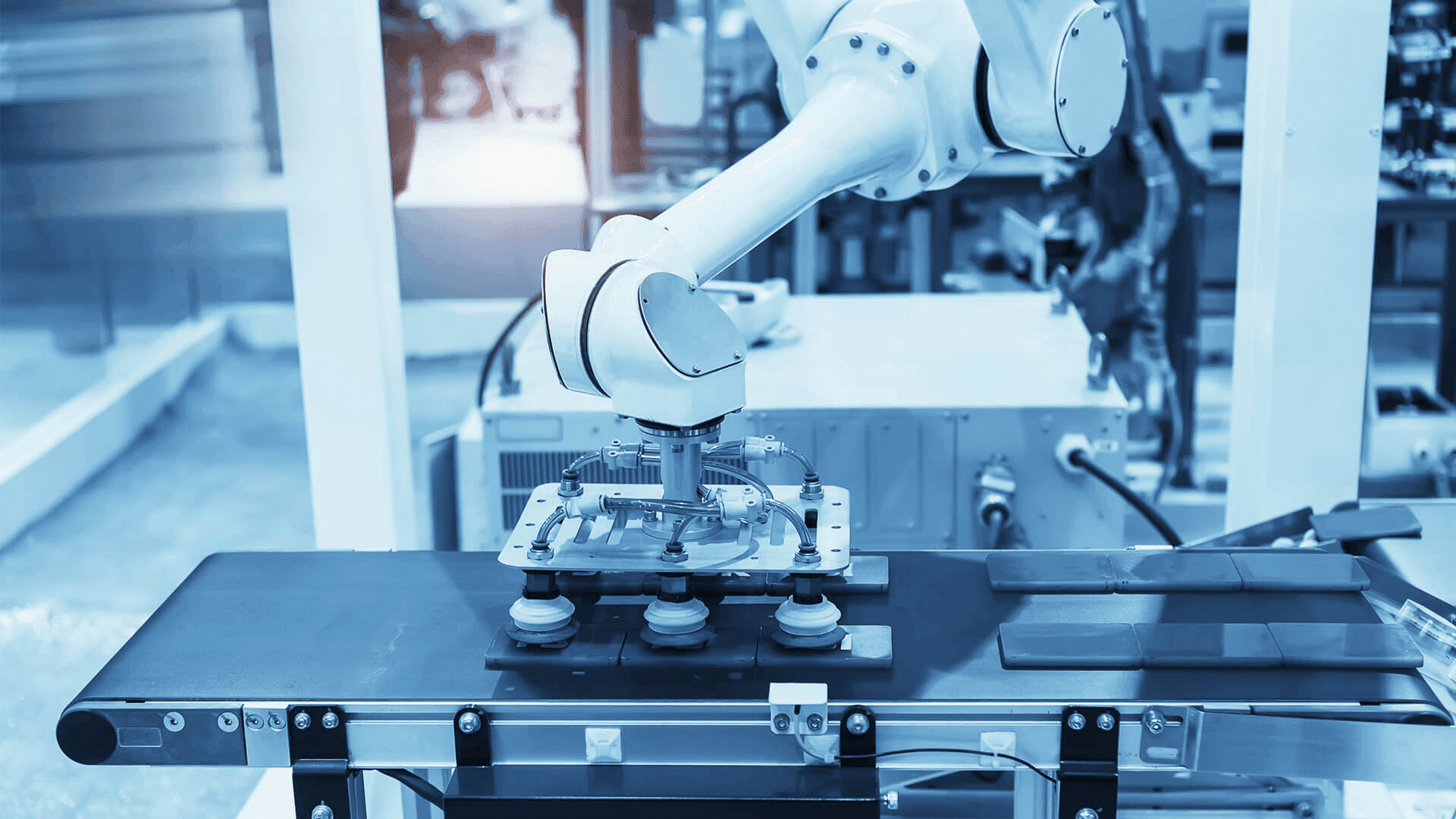

Detecting safety errors & predictive maintenance.

Besides spotting safety errors in real time, AI video analytics allows predictive maintenance by recognizing equipment anomalies prior to their failures.

Derive actionable intelligence

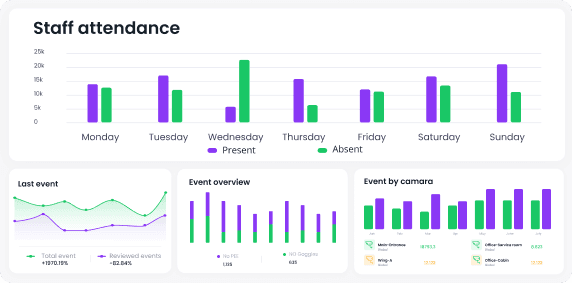

Video analytics in the manufacturing industry helps to demonstrate production performance & health compliance by visualizing aggregated video data into heatmaps and dashboards.

Major use cases of AI video analytics for manufacturing

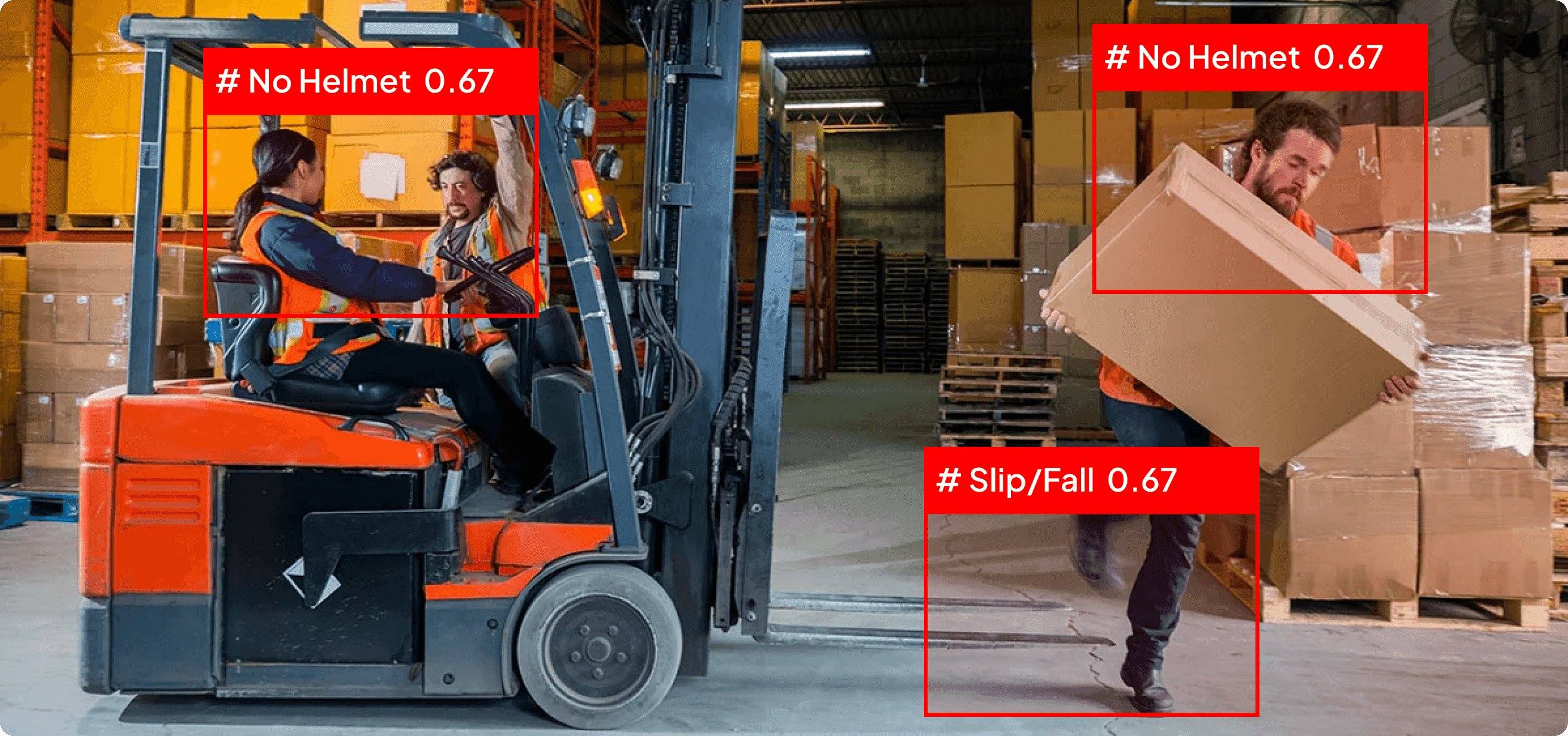

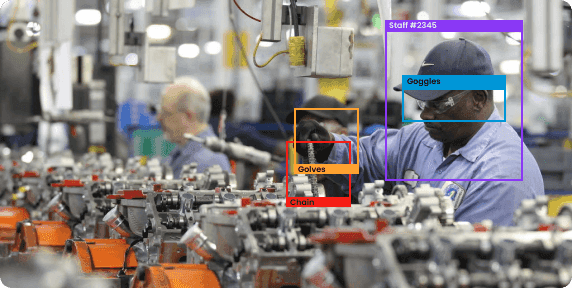

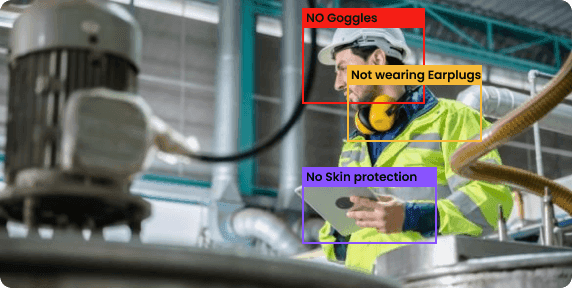

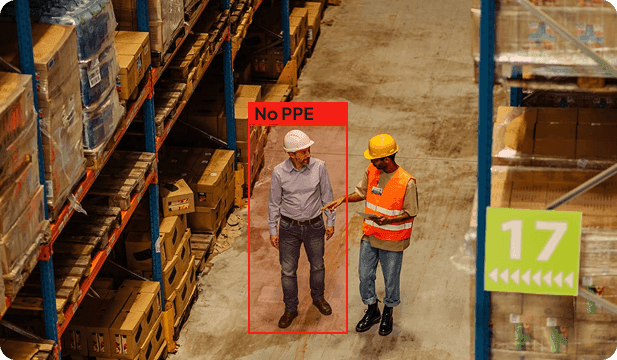

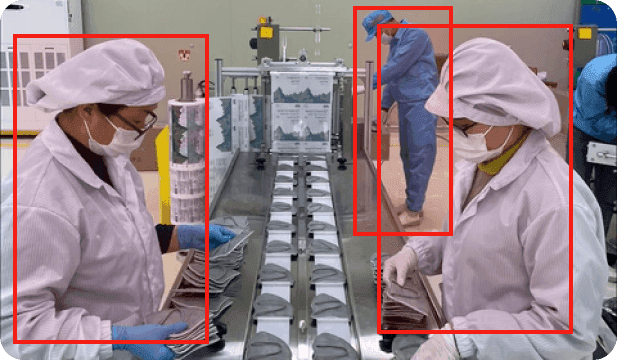

PPE compliance

Improve the workplace safety standards with AI monitoring PPE such as helmets and gloves for ensuring compliance.

Forklift/path safety alerts

Advancing safety alerts with AI that helps to monitor forklifts, premises and sends immediate alerts on detection of collision risks.

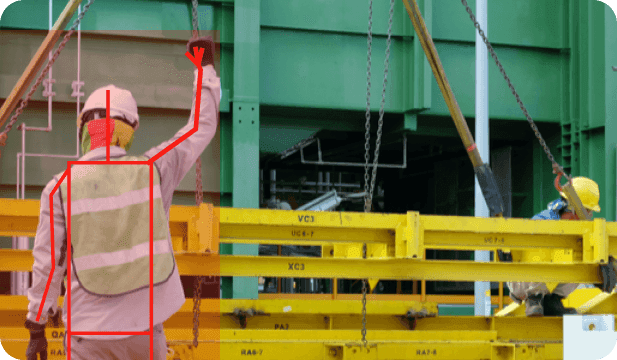

Slip, fall, collapse detection

Harnessing AI analytics software can instantly detect slips and falls, alerting to prevent injuries.

Occupancy monitoring

Track & analyze total number of people present within a space and identify which areas are underused & overcrowded.

Distress gesture detection

Leveraging AI surveillance systems can instantly detect different gestures within a facility, effectively preventing injuries.

Canteen time log detection

Artificial intelligence is capable of tracking timelog of how much time workers are spending in canteen and recess.

What do we offer?

Web dashboard

Get a professional dashboard to offer a complete view of data along with customizable widgets.

Mobile application

With our innovative mobile app platform, users can access valuable data on their devices.

Real–time notifications

Obtain real-time alerts and notifications to stay updated with the latest insights.

Industry-specific applications

We ensure security standards and safety protocols at different stages of a manufacturing unit and offer industry-specific

applications.

F & B manufacture

AI video analytics for manufacturing automates inspection in the food & beverage industry, transforming raw industry into quality products, creating healthier options.

Chemical manufacture

AI video analytics empower chemical manufacturing units with real-time safety and smarter automated operations.

Medical manufacture

Enabling precision quality control and real-time defect detection, AI-powered analytics transform medical manufacturing for smart production.

Industrial manufacture

With modern intelligence, industrial units can automate quality inspection & enforce operations smoothly.

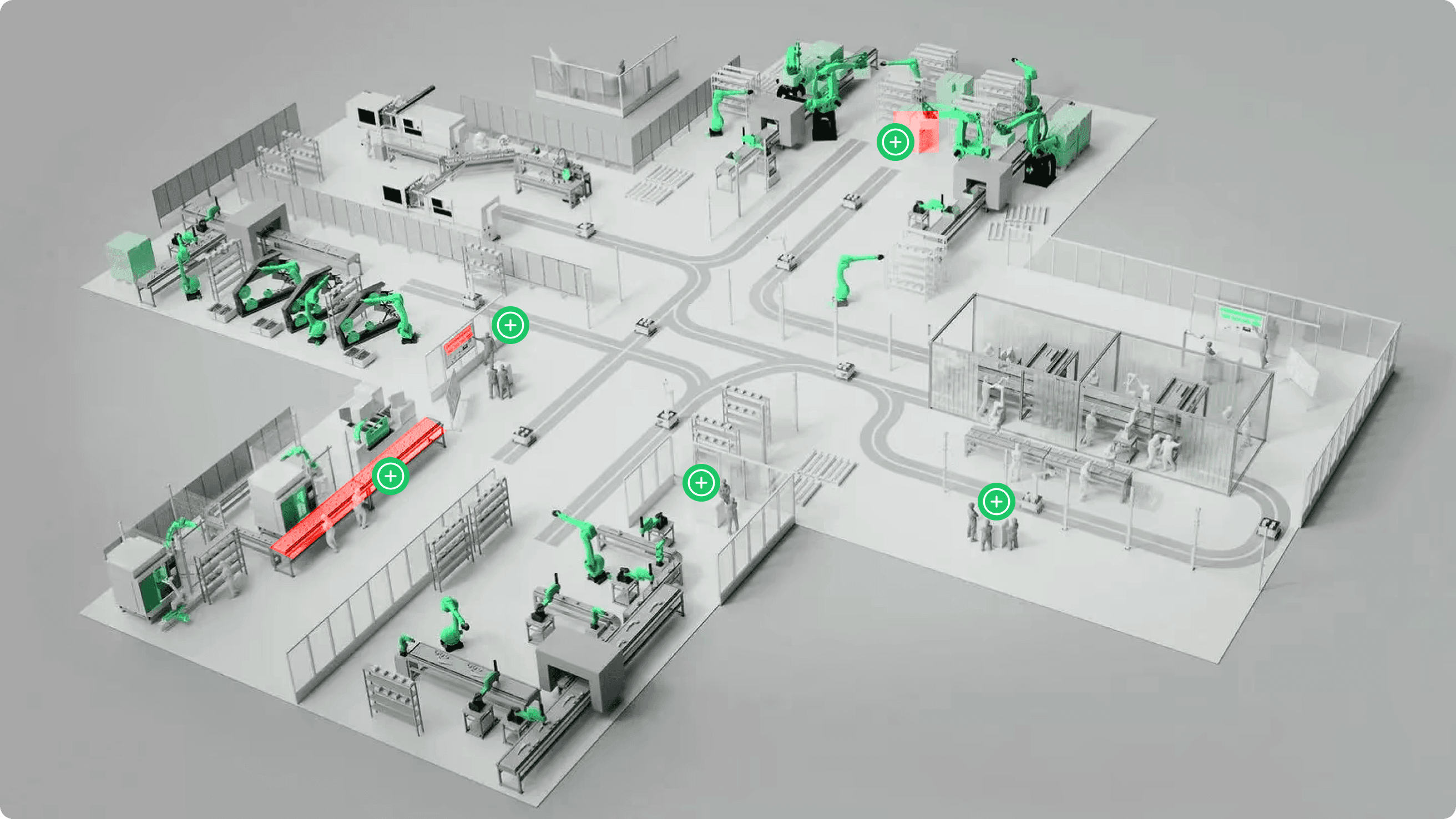

A comprehensive dashboard for how Visionfacts works

Within a manufacturing unit, it is important to keep a close monitoring of the processes. We offer tailored solutions helping

businesses excel across different sectors, leveraging advanced AI technologies.

Key business benefits

We get to the core, delivering measurable improvements across your organization.

1%

Reduction in violations

Effectively detect and address different safety violations, preventing incidents and regulatory penalties.

1%

Reduced insurance costs

Keeping up-to-date with safety standards, demonstrating commitment to safety & lowering worker’s compensation premiums.

1%

Increased productivity

With real-time monitoring of tasks, they can focus on strategic safety improvements.

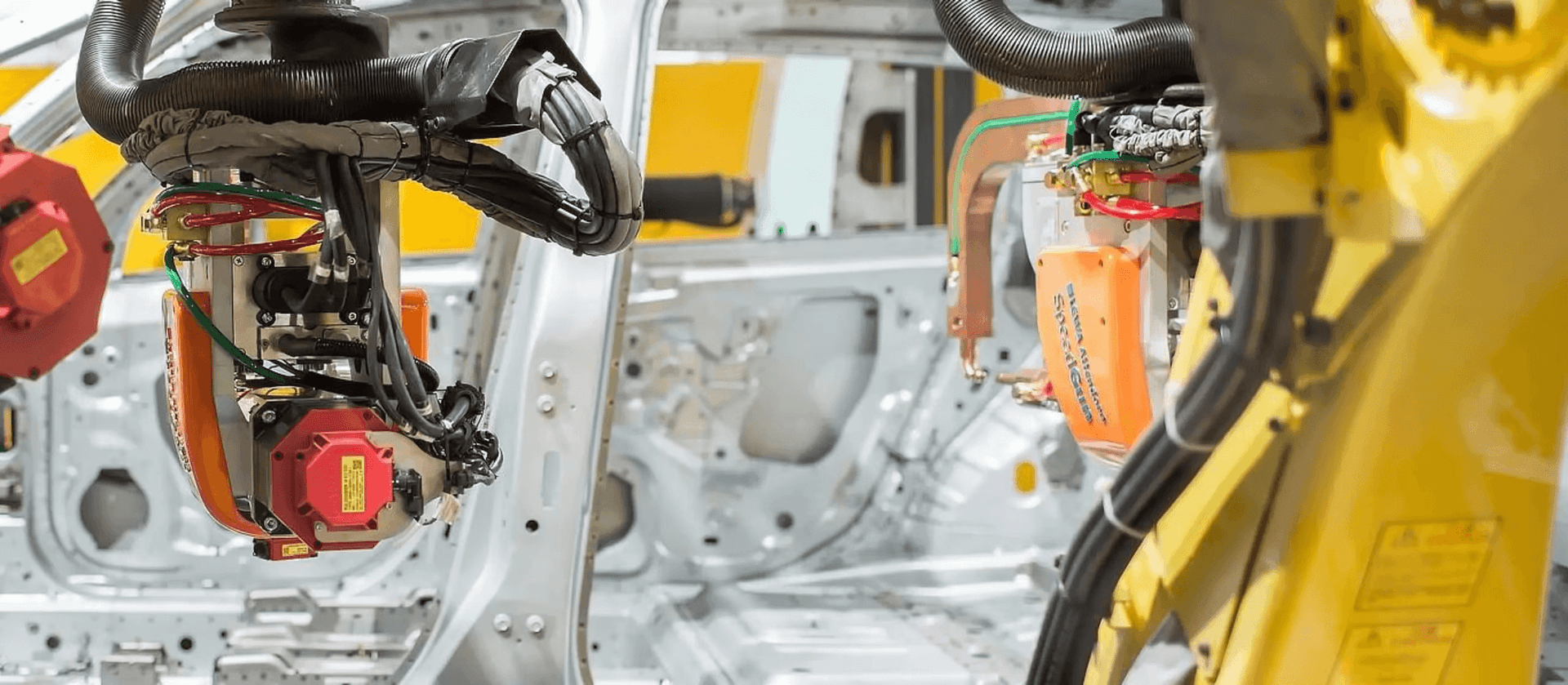

How does our manufacturing quality control system operate?

Visionfacts is developed as a manufacturing quality control system that identifies defects through production line cameras,

utilizing an algorithm trained on diverse manufacturing processes and providing actionable insights based on the data.

Technical flow

An Overview of Visionfacts' Functionality

ROI calculator

The statistics disclose the true costs of workplace safety incidents ensuring proper safety measures for businesses.

Case study

Discover how leading organizations are leveraging video analytics for elevating comprehensive experiences.

AI footfall counting and security monitoring system for Jewellery store – AVR Swarnamahal

Manufacturing production & security monitoring with AI for Haldirams

Frequently asked questions

Your resource for quick answers about our services and support. Find solutions and tips!